Expertise for solving your toughest test challenges

Whether your challenges are big or small, Testeract has the capability to help you meet critical deadlines and get your test system to completion.

From consultation to complete systems, we have you covered.

With Testeract as a partner, you can get your test challenges solved quickly and also get the training to solve future challenges.

Let our experienced test engineers and architects help you determine your path forward for your specific needs.

When deadlines are approaching faster than you anticipated, let us give you a boost with experienced test engineers.

We can help you make sense of your code and offer solutions that solve difficult automated test problems.

Capabilities and Certifications

Testeract has many industry certifications and proven capability to help you with the automated test projects you need. Among them, Testeract is an NI Partner with multiple certified LabVIEW architects, LabVIEW Champions, TestStand Architects, and Certified Professional Instructors. In addition to these certifications, Testeract also has extensive experience working with government projects and is ITAR registered.

NI Certifications

Software Capabilities

Government Certification

See major improvements in test performance

System better than anticipated

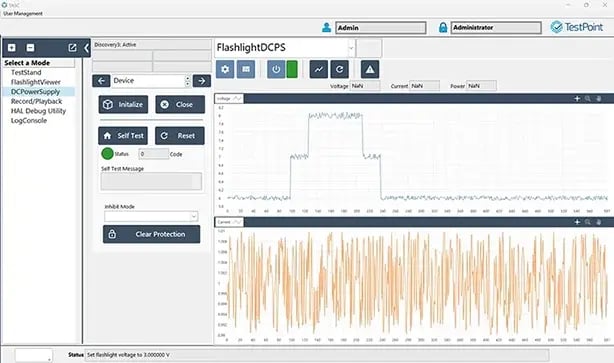

A medical equipment company had been working on a monolithic application for testing ultrasound probes for 3 years without success. Testeract engineers using TestPoint helped them develop a successful application.

Saved 20 years of dev time

One major DoD contractor determined it would take 22 engineers a year to complete their complex test system. With Testeract it took 2 engineers only one year to complete. Read the full case study to learn more.

We're here to assist you

Set up a free consultation around your automated test system needs.